Cable Gland Tightening Guide

The installation of a cable gland can create a major health and safety issue for companies within harsh and hazardous environments.

A gland that has been under tightened may allow water or dust into equipment, or the gland may become loose creating an electric shock risk.

If a gland is over-tightened, the cable’s properties will be compromised, and the equipment may fail, or the cable may become damaged, which can then lead to explosion risk.

To help address issues with the overtightening of cable glands and the resultant damage to cables and seals, Hawke International has developed the patented Inbuilt Tightening Guide.

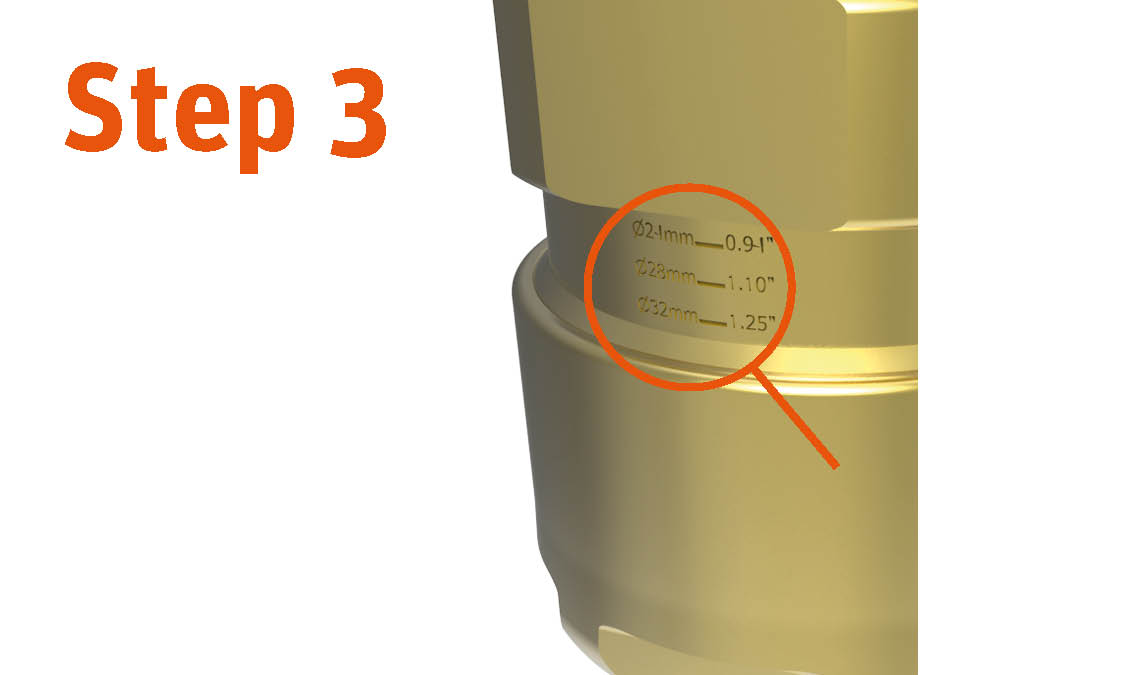

The guide gives the installer and inspector a simple visual indicator, to show the cable gland has been tightened to the corresponding outer diameter of the cable being fitted.

This will therefore reduce the installtion risks within harsh and hazardous environments.

How it works

The gland is permanently marked with various lines/numbers indicating the correct tightening level related to the cable diameter in mm and inches.

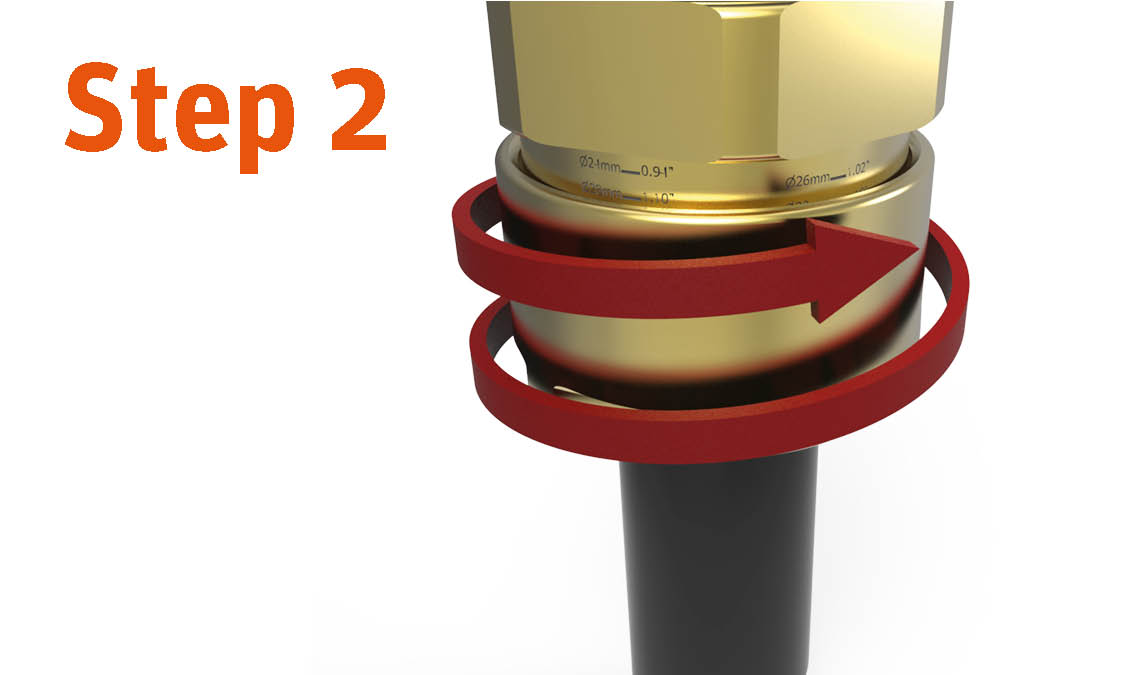

The dome nut has to be tightened according to the relevant assembly instructions.

After tightening, the installer can check the position of the dome nut on the respective marking and compare it with the outer cable diameter.